K Viktor

-

Posts

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by K Viktor

-

-

I thank for your responses!

That is some awesome work you have done. I bet they are spooky fast to ride.Yes, but now i can not choice right rear tire, Michlen Pilot road III slips first 100-150m of race strip, Pirelli Supercorsa too...

My speed record = 325km/h at one mile, this is very bad result for this bike.

Incredible, you definitely have skills to pay the bills.No, i do not pay - it's my work

First bird in this topic - my own, others are builded for clients.

-

AFRs

in The Garage

AFR at low loads/rpm also depends from intake valves clearance. Smaller clearance = leaner target mixture.Okay, I give up. What does valve clearance have to do with AFR? And is that piston-to-valve clearance or valve bucket-to-cam clearance?

Yes, valve to cam clearance. That affect to valve open time and engine volumetric efficiency, as well as changing cam lobe height.

-

Third Bird

This is low-cost low-power project.

FI 1999 CBR1100xx:

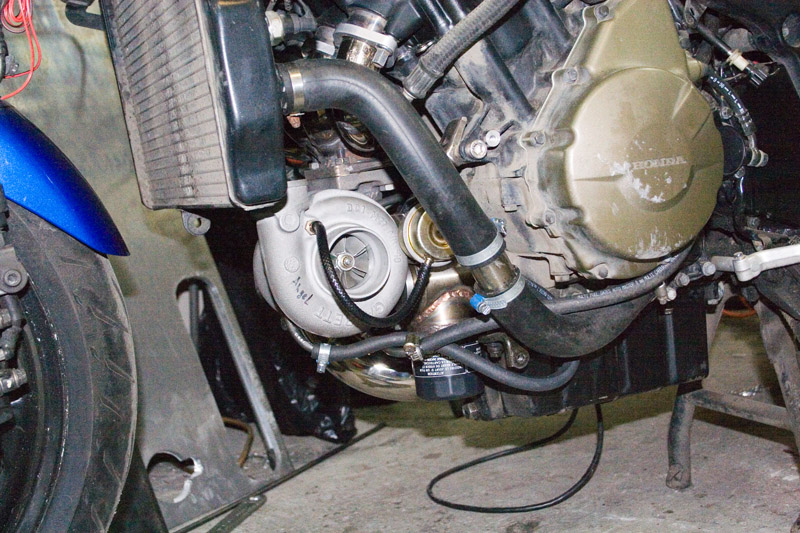

Define correct turbine location:

Some welding work

And CNC work:

Installed HKS SSQV blowoff valve:

"Mockup" installation:

Downpipe. 133 dBa at CEM noise meter

Engine. Thicker Cometic gasket and adjustable CAM sprockets. That's all.

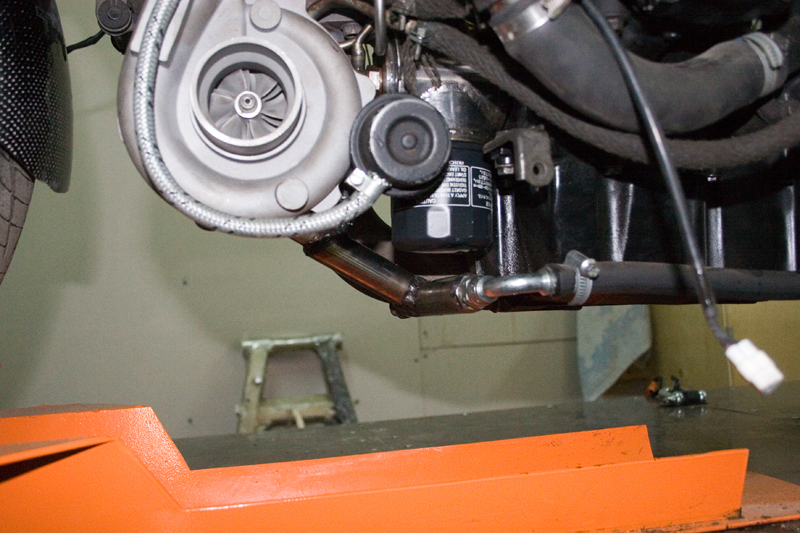

Oil filter adapter. All right reserved, patented

Completed system:

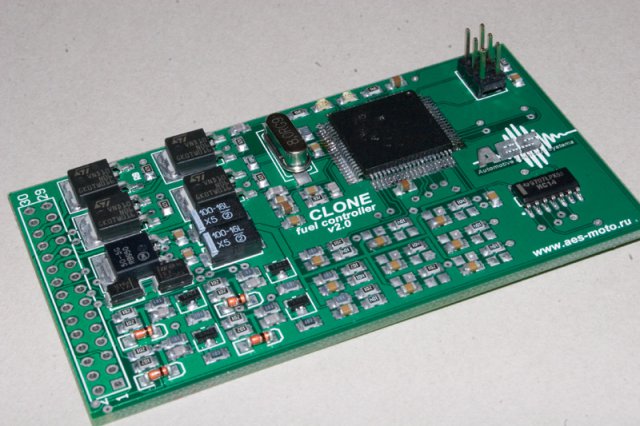

ECU: Stock, with specially designed Fuel Controller, similar to PowerCommander (we called it "CLONE"

) but has ability to boost-control, autotune, MAP-based correction tables and knock sensor input. DAC converter generate fake stock-like map-sensor signal (Bike ECU now happy and FI error on boost not lit):

) but has ability to boost-control, autotune, MAP-based correction tables and knock sensor input. DAC converter generate fake stock-like map-sensor signal (Bike ECU now happy and FI error on boost not lit):

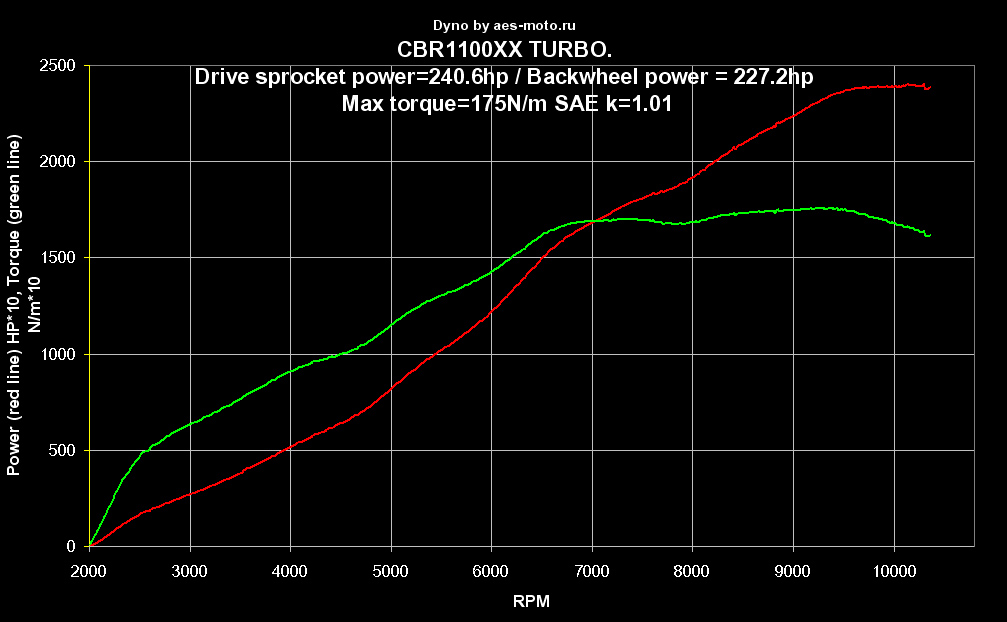

Dynoruns. Very loud

Bird in winter

:

:

Next...

Honda X-11 turbo

This project now in building stage...

-

Second TurboBird

Carbed CBR1100xx 1997 year old.

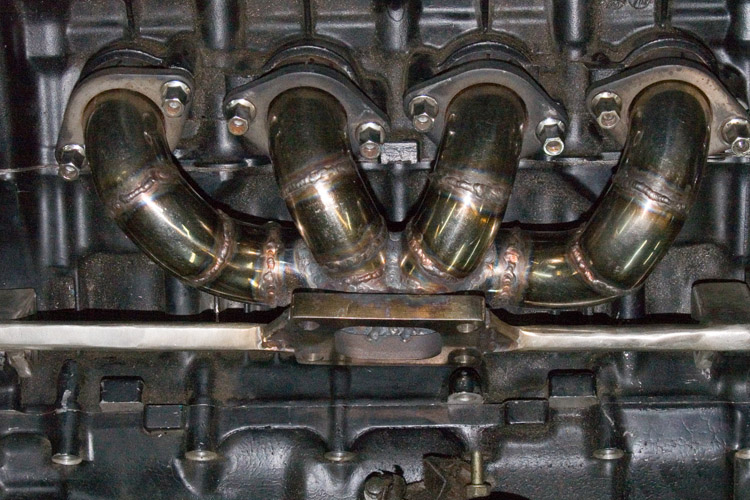

Time to make exhaust flanges:

Russian roads had very bad quality, this is reason for made addition turbine support (without it turbine header may crack). In CATIA software I calculate required arm sizes (to turbine flange):

Welding process:

Turbo intake plenum (receiver):

Engine rebuild (custom pistons, gasket, clutch, etc). Also we changed cylinder head to 2000 year injector. Now we have 1997 fuel injected BlackBird!

ECU similar to 1-st bird, DIY on STM32F103 controller.

Installed pipe connection for turbo oil drain line. Pay attention, it over oil level !

Turbo Engine installed:

Downpipe connected to stock exhaust system:

Intake installed:

AEM UEGO wideband gauge and boost pressure gauge:

Now we have absoluttely "stock-like" 1997 bird, but it FI with turbo engine

-

1

1

-

-

Hello!

I would like to tell about some turbo projects which I build in Russia at last year.

Sorry for my bad english

First, FI Blackbird 2000.

It has Garrett-17 turbo, but his housings overbored to 2860 size. We got similar performance as 2860 but smaller size.

Turbo header: TIG-welded, stainless steel.

Installed 4 EGT sensors, it necessary to accurately monitoring turbine temp. because we use launch-control modes (when clutch disengaged, throttle=100%, ignition advance= 0..-5 degrees and RPM limit in 5000, this helps to build boost at low rpm).

Oil filter rotated to 90 degrees, and oil to turbo gets from its adapter.

Drain line connected to electrical oil scavenge pump locaded under a fuel tank.

Downpipe - simple 60mm stainless steel tube, connected to Devil muffler. Wideband AFR sensor inside

Engine. Custom pistons for 9:1 compression ratio, made specially for me in military factory:

Connection rods are stock (now i want buy Carrillo's), Cometic head gasket.

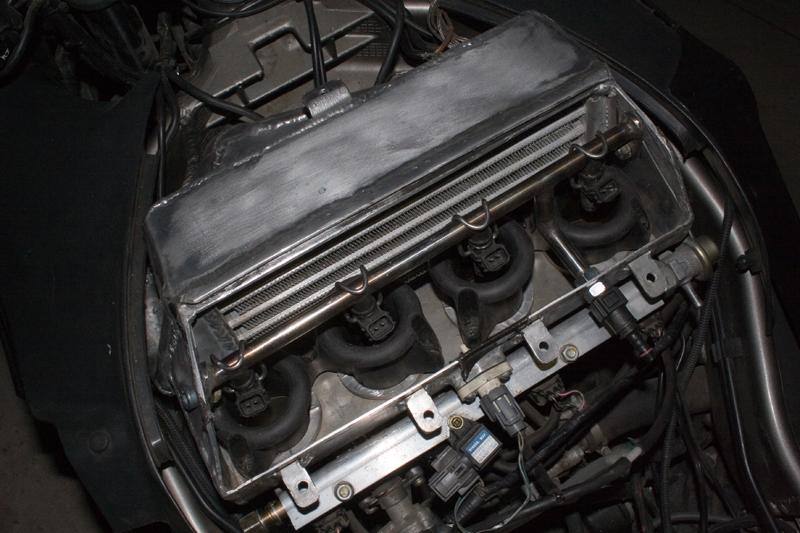

Intake plenum has velostacks, water intercooler and secondary injector rail (from honda S2000). Installed Water-Methanol injection system from AEM.

Blow off valve is simple, but it work very well:

Spark and Fuel management system (ecu) designed specially for this bike, based on Cortex-m3 (stm32f103) controller.

This bird has 257.6 SAE bwhp or 297.2 hp with methanol injection.

Very fun ride ©Elton

Turbo Blackbird:

This is first Russian Turbo Blackbird

Now it has extenden swingarm, electronic traction and boost control.

Second and third birds at next posts!

-

AFRs

in The Garage

AFR at low loads/rpm also depends from intake valves clearance. Smaller clearance = leaner target mixture.

Turbo birds from Russia

in The Garage

Posted

No, i didn't try. Now i want try shinko 003. If it will be slips again, i will order Mickey Thompson. Or 220 wheel

Yes, we don't have compound in our track

Moto dragracing? Russian's don't know what is it

Boost control. hmmm, there are some difficulties:

1) Minimum boost controlled pressure = minimum wastegate opening pressure. It defines by wastegate spring hardness. BUT. In internal wastegate we can not use spring softer then 40% of max boost pressure. Otherwise backpressure open wastegate valve and we have power losses at max boost.

e.g. Max boost = 1.5bar. Then, directly connected wastegate must open at 0.6bar or greater.

Result = minimum boost-controlled pressure = 0.4-0.6bar.

2)Bird completely slips at 0.3bar at launch

Now i think about electrical actuator of wastegate valve. And 220 rear wheel.